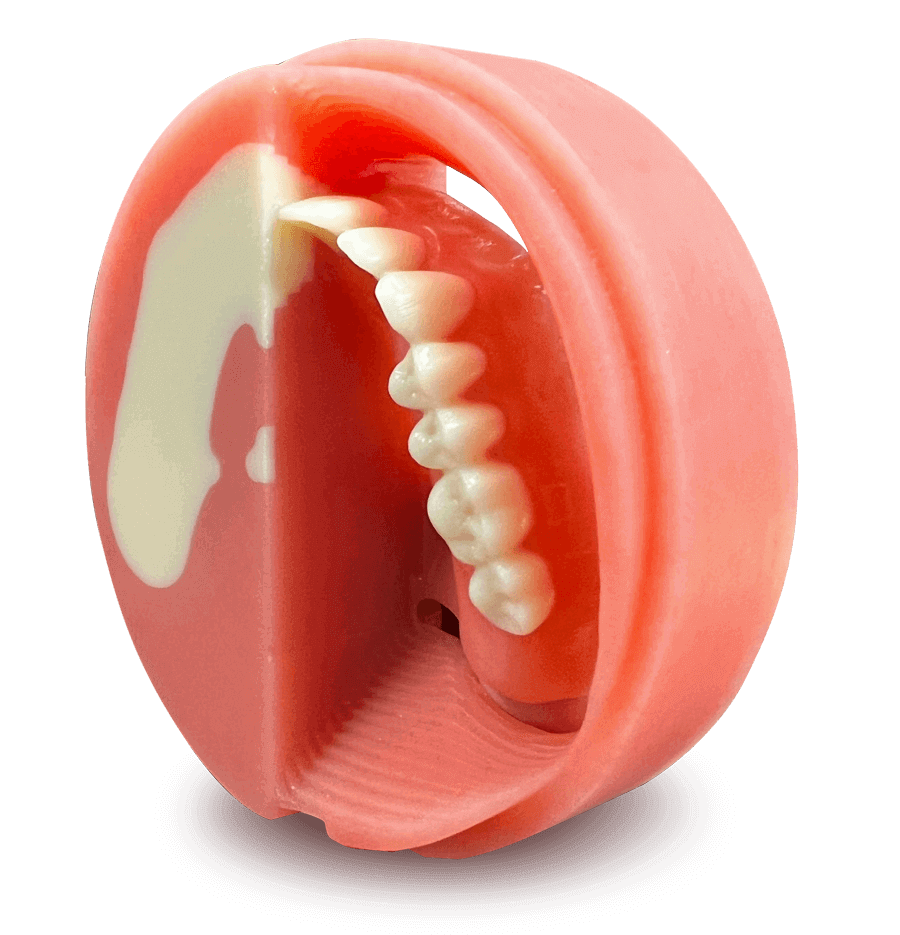

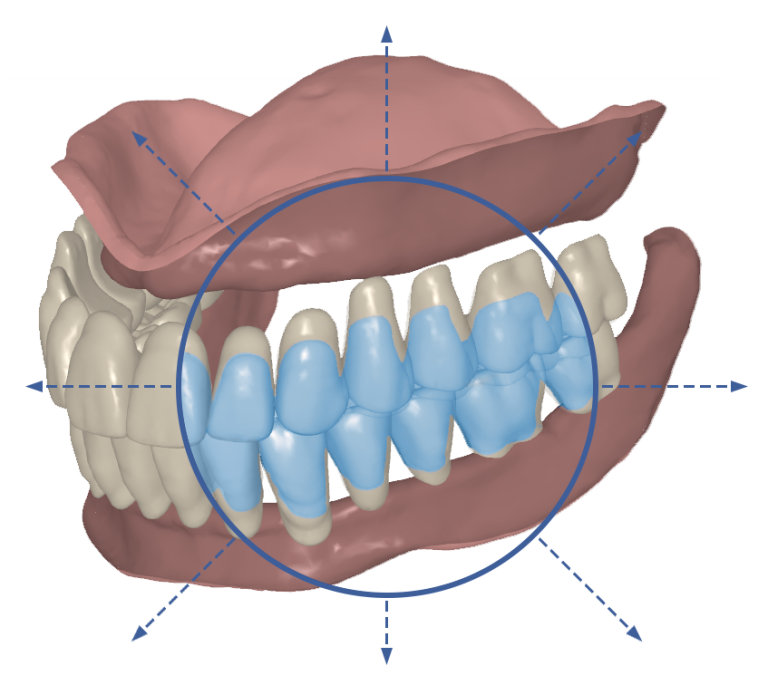

Using the power of Computer Aided Engineering (CAE) and our patented AvaDent eXtreme-Cross-Linked (XCL) materials , technology and manufacturing processes, we offer fully milled, one-piece monolithic denture.

Dentures have been manufactured using lost-wax technology for centuries. AvaDent was the first to disrupt these conventional techniques with a digitally designed denture by creating software and manufacturing systems specifically for removable dentures. 80 patents later, AvaDent’s esthetically driven, precision-fit dentures deliver the ideal occlusion, they’re stain/bacteria resistant and provide unsurpassed strength. This translates into reduced chair time, happy patients, and practice profitability.